Why ASTM E1105 is Essential for Modern Building Projects in California, Arizona, or Nevada

Why ASTM E1105 is Essential for Modern Building Projects? Well, to begin with, the ASTM E1105 Standard Test Method is the go-to test for the Field Determination of Water Penetration of Installed Exterior Windows, Skylights, Doors, and Curtain Walls throughout the United States.

Why ASTM E1105 is Essential for Modern Building Projects? Well, to begin with, the ASTM E1105 Standard Test Method is the go-to test for the Field Determination of Water Penetration of Installed Exterior Windows, Skylights, Doors, and Curtain Walls throughout the United States.

In the world of construction, quality assurance is paramount. I mean, it really keeps the subcontractors on their toes so to speak. One key aspect of this is ensuring the integrity of a building’s envelope which includes the building’s walls, windows, and doors.

This is where ASTM E1105 comes into play. It’s a standardized test method that we administer for water penetration of exterior windows, skylights, doors, and curtain walls. It’s the most widely used standardized test implemented for procuring water or rain leaks within these systems.

But why is this water intrusion test so important?

The ASTM E1105 is the gold standard for testing windows, doors, walls and more in Arizona, California, and Nevada.

The simple fact is that water intrusion caused by rain leaks can lead to serious issues. Water intrusion can contribute to the direct cause of mold growth, and structural damage, and it can even reduce a building’s overall lifespan.

In essence, the ASTM E1105 test when we administer it can help to prevent these problems. In a nutshell, the test assesses the performance of building envelope, ensuring they meet specific design requirements.

It is the Gold standard for rain leak testing hands down and is widely recognized in the construction industry as being the only test necessary for water testing. Moreover, the test is often specified in the ICC building codes and most project specifications.

Contact for more information

For ASTM E1105 Testing information click this button and fill out our form and we'll contact you ASAP

Click Me!ASTM E1105 is Not Just About Preventing Water Damage

ASTM E1105 is not just about preventing water damage. It’s also about promoting sustainable building practices. This is achieved by ensuring airtight and watertight building envelopes. This specific test can lead to huge energy savings by preventing unnecessary resource depletion due to water or air infiltration and subsequent repairs as a result.

For one thing, this test is administered worldwide however, it’s particularly relevant in regions like Los Angeles, Arizona, and Nevada. Areas such as these, have extreme and sometimes varying climates which can exacerbate water intrusion problems within the building envelope.

At the same time, the ASTM E1105 Standard Test Method for the Field Determination of Water Penetration of Installed Exterior Windows, Skylights, Doors, and Curtain Walls, is also a tool for risk management in construction projects. Utilizing this test will aid in identifying design or installation flaws that could lead to water intrusion. Many of these flaws once discovered can usually be applied to the entire project making prevention even that much more important.

Used as a benchmark for quality assurance in the fenestration industry

Used as a benchmark for quality assurance in the fenestration industry. Administering the ASTM E1105 test can indicate that a building’s envelope can handle a certain level of water exposure without leakage. Whether the water exposure is a little or a lot it nevertheless brings to light these damages to be repaired.

Throughout this article, we’re gonna delve a little deeper into what makes the ASTM E1105 test a key component for most new commercial or modern residential building projects. We’ll explore its key components, its role in construction quality assurance, and its real-world applications.

So, whether you’re a construction professional, a building owner, or simply interested in building maintenance and quality assurance, stay tuned. This article is for you.

Introduction, the Understanding of the ASTM E1105 Field Test

What is the ASTM E1105 test? For starters, there are very few standardized comprehensive tests that were developed for the sole purpose of using water or air to determine whether or not a window or door is serviceable. This test is designed to evaluate water penetration in multiple different building components. Specifically, targeting exterior windows, skylights, doors, and curtain walls.

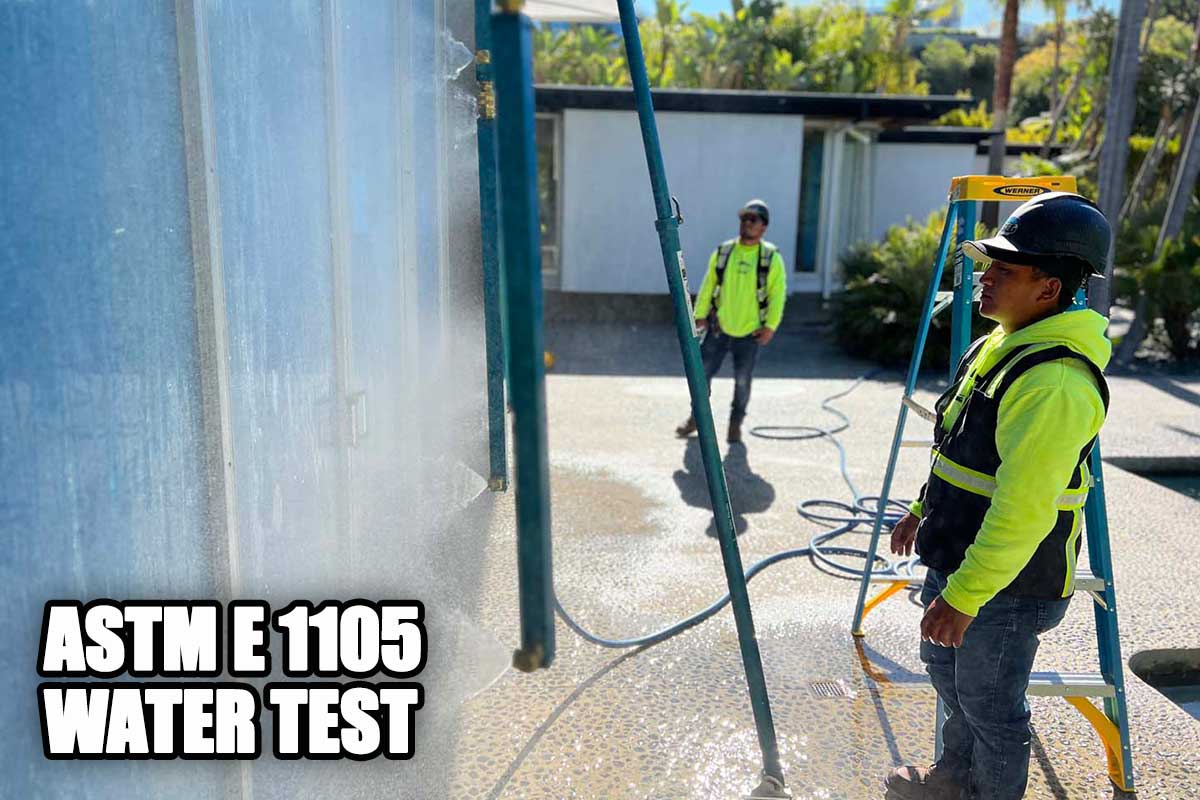

Our test simulates conditions that buildings face in reality, like genuine rainfall. With the addition of a vacuum, the test can create a controlled environment like a wind-driven rain event to assess how well these building systems resist water infiltration. When the test is administered correctly it highlights vulnerabilities in both design and installation.

Much like other tests from the AAMA and ASTM, this procedure involves using the calibrated spray rack system. This system delivers water to the exterior surface of the test specimen resembling genuine rainfall. When administered correctly the test requires a precise flow rate and air pressure to reflect realistic weather conditions like rain.

One of the most versatile features of ASTM E1105 is its ability to test various settings. Whether uniform static air pressure or cyclic conditions, it adapts to suit different scenarios. This flexibility ensures accurate assessments for diverse building designs and climates like in Arizona, California, or Nevada.

Moreover, ASTM E1105 is part of a larger picture in building standards. It aligns with other tests like ASTM E783, which focuses on air leakage testing. Together, they provide a comprehensive understanding of a building’s envelope integrity.

TEST STANDARD

What does the ASTM E1105 document say?

1. Scope

1.1 This test method covers the determination of the resistance of installed exterior windows, curtain walls, skylights, and doors to water penetration when water is applied to the outdoor face and exposed edges simultaneously with static air pressure at the outdoor face higher than the pressure at the indoor face.

1.2 This test method is applicable to any curtain-wall area or to windows, skylights, or doors alone. It is intended primarily for determining the resistance to water penetration through such assemblies for compliance with specified performance criteria, but it may also be used to determine the resistance to penetration through the joints between the assemblies and the adjacent construction. Other procedures may be appropriate to identify sources of leakage.

1.3 This test method addresses water penetration through a manufactured assembly. Water that penetrates the assembly, but does not result in a failure as defined herein, may have adverse effects on the performance of contained materials such as sealants and insulating or laminated glass. This test method does not address these issues.

AAMA and ASTM Window, Wall and Door testing | The Importance in Modern Construction

The significance of ASTM E1105 goes beyond mere testing. In modern construction, it serves as a cornerstone of building envelope validation. Water intrusion poses a significant threat to construction projects both new and existing. From mold growth to structural degradation, unchecked moisture leaks can lead to severe structural consequences. Therefore, having a reliable standard like ASTM E1105 is indispensable.

It’s important to realize that incorporating this test into brand-new building projects ensures adherence to quality assurance. This test like others that are similar, not only meets regulatory requirements but also enhances the durability of structures. Builders and architects use the ASTM testing standards prioritize the use of them to prevent costly repairs and maintain high standards.

Regions like Los Angeles, Arizona, and Nevada, with diverse climatic challenges, exemplify its relevance. In such areas, ASTM E1105 helps adapt construction practices to withstand environmental pressures. This adaptability is crucial for developing resilient and long-lasting buildings.

Here are key reasons why ASTM E1105 matters:

- Prevents water damage: Keeps buildings free from mold and structural issues.

- Ensures quality: Promotes high standards across construction projects.

- Supports sustainability: Encourages energy-efficient and eco-friendly designs.

- Mitigates risk: Identifies potential flaws before they lead to significant problems.

Unquestionably, by understanding and utilizing ASTM E1105, construction professionals can deliver more robust, sustainable, and reliable buildings. This ultimately benefits the industry as a whole, ensuring structures are safer and better suited to withstand various environmental challenges.

Key Components of ASTM E1105

Scope of the Standard

The scope of ASTM E1105 is extremely extensive and is a very detailed document. It provides a clear framework for evaluating water penetration resistance. This standard is vital for fenestration products such as windows, doors, skylights, and curtain walls. In essence, the aim is to test these systems under simulated weather conditions. By doing this, applying this standard helps ensure that buildings maintain their integrity against environmental stresses like wind and water. The scope of this test includes new constructions and renovated or repaired building structures.

ASTM E1105 is versatile and adaptable which is the Gold standard in new construction testing. This applies to various building types and climates, from arid regions like Arizona, Los Angeles, and Nevada to areas with frequent rain. The test’s adaptability means it is an essential part of construction projects nationwide. It supports the building envelope’s resilience and performance.

Testing Procedures

ASTM E1105 employs a systematic approach to testing. Applying the procedure aims to replicate real-world conditions that challenge a building’s resistance to water intrusion.

- First, the test begins with setting up a calibrated spray rack system. This spray rack system is positioned to apply water uniformly across the surface.

- After which the spray pattern is very specific.

- Once the water is on, the water pressure and flow rate are adjusted based on test requirements to mimic actual rainfall and wind conditions.

- Next, the static air pressure in the test chamber is controlled by way of a vacuum system. This simulates the pressure or conditions of wind-driven rain. By varying the pressure, testers can assess how, visually, water might penetrate these structural components during rain storms.

- Finally, monitoring the entire testing process is a crucial part of the process. Observers are on the interior of the building and check for water leakage signs inside the building during the test duration.

- Once completed, a report is written. Any water infiltration noted is documented carefully, providing insights into potential vulnerabilities.

Our testing procedure includes both uniform and cyclic pressure methods. Uniform static pressure involves applying a constant air pressure difference, whereas cyclic testing alternates pressure, imitating gusty wind conditions.

TEST STANDARD

What does the ASTME1105 Test Standard Say?

12. Procedure

12.1 Procedure A—Test under uniform static air pressure difference as follows:

12.1.1 Adjust the valve on the water-spray system so that the intake water is being delivered at the calibrated pressure, as described in Section 9.

12.1.2 Apply the specified static air pressure difference within 15 s and maintain this pressure, along with the specified rate of water spray, for 15 min.

12.1.3 Observe and note points of water penetration, if any, that occur during the test.

12.1.4 Remove the air pressure difference and stop the water spray. Carefully inspect the test specimen for any additional evidence of water penetration and note any such evidence for the report.

Procedure B—Test under cyclic static air pressure difference as follows:

12.2.1 Adjust the valve on the water-spray system so that the intake water is being delivered at the calibrated pressure, as described in Section 9.

12.2.2 Apply the specified static air pressure difference across the test specimen promptly and maintain this pressure, along with the specified rate of water spray, for the period stipulated by the specification or the specifier. Unless otherwise specified, the duration of the pressure cycle shall be 5 min.

12.2.3 While maintaining the water spray, reduce the air pressure difference to zero for not less than 1 minute.

12.2.4 Repeat the preceding two steps for the specified number of cycles. In no case, however, shall the total time of pressure application be less than 15 min.

12.2.5 Observe and note points of water penetration, if any, which occur during the test.

12.2.6 After the required number of cycles, remove the air pressure difference and stop the water spray. Carefully inspect the test specimen for any additional evidence of water penetration and note any such evidence for the report.

12.3 Measure and record the barometric pressure and temperature of the air near the exposed surface of the test specimen, and of the air near the air intake or exhaust of the air system. Measure and record the speed and direction of the air movement (wind) at or near the exposed surface of the test specimen. Take such measurements immediately before or

during the test.

Key steps in the testing procedure include:

Preparation: Setting up calibrated equipment and preparing the test specimen.

Application: Using a spray rack to deliver water at a specified rate.

Pressure Control: Adjusting internal pressure to simulate wind-driven conditions.

Monitoring: Observing, documenting, and analyzing any water penetration.

This structured approach allows construction teams to identify weak points in building envelopes. It provides vital data for future improvements.

Equipment Used

It’s important to understand that the ASTM E1105 relies on specialized equipment, such as the calibrated spray rack, vacuum system, and an air pressure measurement device to ensure accurate results. Our professional testing equipment must meet specific standards to mimic real-world conditions effectively. One of the core tools is the calibrated spray rack system. This system spray rack delivers water consistently across test surfaces. Each nozzle must function precisely as designed to maintain the correct flow rate and pressure.

The vacuum and pressure chamber along with the air pressure measurement devices are also essential. They create the controlled pressure environment required for testing. This equipment must sustain accurate pressure variations to replicate different wind conditions with surprising accuracy. Recording equipment captures and logs data throughout the test. It provides a detailed record of water penetration events, ensuring a comprehensive assessment of the building envelope.

Essential equipment includes:

Spray rack system: A calibrated piece of equipment that sprays water over a specimen with even water application.

Air pressure devices: Air pressure devices are used to simulate wind effects accurately.

Recording tools: We use recording devices to document water penetration occurrences.

With these tools, ASTM E1105 offers a reliable method to evaluate how well fenestration products resist water intrusion. This process ensures that buildings can withstand environmental challenges, promoting durability and safety.

The tools or apparatus used to perform the ASTM E1105 test

6. Apparatus

6.1 The description of apparatus in this section is general, and any arrangement of equipment capable of performing the test procedures within allowable tolerances is permitted.

6.2 Major Components (Fig. 1):

6.2.1 Test Chamber—A test chamber or box made of plywood, plastic, or other suitable material and sealed against the test specimen. Test chambers mounted on the interior must be made so that interior surfaces and joints of the specimen can be easily observed for water penetration during the test. No part of the testing chamber shall come in contact with or restrict any point where water penetration may occur. At least one static air pressure tap shall be provided to measure the chamber air pressure versus the ambient (interior-exterior) air pressure and shall be so located that the reading is unaffected by exterior impinging wind, or by the velocity of air supply to or from the chamber. The air supply opening into or exhaust from the chamber shall be arranged so that air does not impinge directly on the test specimen with any significant velocity. A means of access to the chamber may be provided to facilitate adjustments and observations after the chamber has been installed. supply exhaust system or reversible blower designed to supply the required maximum air pressure difference across the specimen. The system must provide essentially constant airflow at a fixed pressure for the required test period.

6.2.3 Pressure Measuring Apparatus—A device to measure the test pressure difference within a tolerance of 62 % or 60.01 in. (62.5 Pa of water column), whichever is greater.

6.2.4 Water-Spray System—The water-spray system shall deliver water uniformly against the exterior surface of the test specimen at a minimum rate of 5.0 U.S. gal/ft2·h (3.4 L ⁄m2·min).

6.2.4.1 The water-spray system shall have nozzles spaced on a uniform grid, located at a uniform distance from the test specimen, and shall be adjustable to provide the specified quantity of water in such a manner as to wet all of the test specimens, uniformly and to wet those areas vulnerable to water penetration. If additional nozzles are required to provide uniformity of water spray at the edge of the test specimen, they shall be equally spaced around the entire spray grid.

6.2.4.2 The intake water line to the nozzle grid shall be equipped with a pressure gauge and pressure adjusting valve. For field testing, the water pressure shall be adjusted to the same pressure at which the water spray system was calibrated.

The Role of Construction Quality Assurance is to Ensuring Water Penetration Resistance

Ensuring water penetration resistance is critical in construction. The use of the ASTM E1105 plays an indispensable role in this endeavor. When applied, it acts as a quality benchmark for evaluating fenestration products against many different types of water intrusion risks. Water penetration can severely damage building structures. It leads to mold growth and compromises structural integrity. By identifying these vulnerabilities early, ASTM E1105 aids in the construction quality assurance process.

The test provides builders and architects with the data needed to make informed decisions. They can use the results of the E1105 test to enhance the building’s design features and improve construction methods. This proactive approach ensures buildings are better equipped to handle adverse weather conditions. Moreover, the standard’s systematic testing procedures are crucial to locating air leaks or water infiltration to provide needed data used to improve building design. In addition, testing like this helps construction teams identify potential flaws in design and installation. Detecting and rectifying these issues ensures a resilient barrier against water or air ingress.

TEST STANDARD

What does the ASTM E1105 test standard stay?

Summary of Test Method

4.1 This test method consists of sealing a chamber to the interior or exterior face of the specimen to be tested, supplying air to a chamber mounted on the exterior or exhausting air from a chamber mounted on the interior, at the rate required to maintain the test pressure difference across the specimen while spraying water onto the outdoor face of the specimen at the required rate and observing any water penetration.

Impact on Building Longevity and Durability

If there’s anything to be taken from the ASTM E 1105 water intrusion test is that it is designed to better a building’s performance now and in the future. A building’s longevity and durability are top priorities in construction hands-down. Quality assurance testing like the 1105, plays a vital part in these objectives. ASTM E1105 testing contributes significantly to both aspects through its rigorous assessments.

By simulating realistic weather conditions, the standard reveals weaknesses that might otherwise remain unnoticed. Addressing these issues during construction or renovation extends the lifespan of building components. This mitigates the long-term impact of water-related damage.

Durability is not just about withstanding the forces of nature. It’s also about maintaining a building’s visual and structural integrity over time. ASTM E1105 helps achieve this by testing how well various construction materials resist water intrusion. Ensuring that fenestrations such as windows and doors perform optimally can prevent costly repairs. It also maintains property value and ensures the comfort and safety of occupants.

In the broader context, ASTM E1105 aligns with sustainable building practices by promoting efficient resource use. By preventing premature material failure, the test reduces waste and supports environmental conservation efforts.

Ultimately, incorporating ASTM E1105 into your building projects is a testament to prioritizing excellence in construction. It actually stands as a commitment to delivering structures that are not only resistant but enduring.

Building Envelope Testing and Importance of a Robust Building Envelope

A building envelope functions as the primary barrier against environmental elements. Its robustness directly impacts energy efficiency, comfort, and durability. This makes building envelope testing an essential practice in modern construction.

A well-designed envelope separates the indoor and outdoor environments effectively. It regulates temperature and humidity while maintaining indoor air quality. This control reduces energy costs, contributing to overall building efficiency.

The building envelope also plays a crucial role in protecting structural integrity. By preventing moisture ingress, it averts potential damage to materials and finishes. Therefore, you can see how regular testing of the envelope’s integrity is a proactive step in preserving long-term building performance.

Moreover, a robust envelope enhances occupant comfort and well-being while occupying the structure. It minimizes drafts, reduces noise transmission, and regulates thermal conditions. This creates a more enjoyable and healthy living or working environment, which is vital in densely populated regions.

Common Issues Detected During Water Intrusion Testing

It is worth noting that when we perform these tests soon buildings, the building envelope testing often reveals several commonly found issues. These issues, if undetected, can lead to significant problems over time. The primary concerns relate to moisture management, air leakage, and thermal bridging.

Moisture management: Moisture intrusion is a prevalent problem in building envelopes. It can result from various sources, such as leaks around windows or roofs. Left unchecked, moisture can cause mold growth and material deterioration.

Air leakage: Air leakage is another frequent issue identified during envelope testing. Gaps and cracks in the building’s shell allow air to escape or enter. This compromises energy efficiency and comfort, leading to increased heating or cooling demands.

Thermal bridging: Thermal bridging occurs when heat transfers through less insulated components. This results in energy loss and potential condensation problems. Identifying and mitigating these bridges is crucial for maintaining the building’s energy efficiency.

Detection of these issues necessitates immediate action to prevent escalation. By addressing these weaknesses early, construction professionals can avoid costly repairs. They ensure that the building envelope remains protective and efficient throughout its lifespan.

Real-World Applications and Case Study: Los Angeles Developments

In Los Angeles, Arizona, and Las Vegas, building projects often face unique challenges due to the severe climate changes seasonally. These cities experience both wet winters and very dry summers, increasing the risk of water intrusion significantly. This makes ASTM E1105 testing an invaluable tool for local developments.

A recent project in downtown Phoenix highlights the importance of ASTM E1105. The development team implemented thorough building envelope testing to ensure quality construction. By identifying potential weaknesses, they could address issues before occupancy, saving time and resources.

Moreover, most developers work closely with water intrusion specialists like building leak detection companies to fine-tune design elements. This collaboration between building officials and water intrusion experts lead to enhancements in window and door installations, reducing the risk of leaks. As a result, the project not only met but exceeded local building codes and quality expectations.

These professionals in large cities like Las Vegas, Phoenix, and Los Angeles are recognizing the return on investment that ASTM E1105 offers. Successful testing in projects like these not only safeguards their properties but also boosts investor confidence. This proactive approach helps mitigate future liabilities related to water damage.

Implementation in California, Nevada, and Arizona

California, Nevada, and Arizona each present unique environmental challenges for construction. These states face varied climate conditions that demand robust building practices. ASTM E1105 testing plays a critical role in managing these diverse challenges.

In California, especially along the coast, buildings must withstand strong winds and rain close to the ocean. By using ASTM E1105, developers ensure their buildings can resist water intrusion from wind-driven rain. This testing is integral to preserving the state’s valuable real estate investments.

Nevada on the other hand, experiences harsh desert conditions, with high temperatures and occasional storms. Building envelopes in this region must contend with thermal stress and potential water ingress. ASTM E1105 provides a standardized way to test and improve these envelopes for better performance.

Arizona faces a similar climate to Nevada, with intense heat and monsoon rains. Water intrusion testing helps prepare structures to deal with sudden weather changes. Building envelope testing is particularly crucial in cities like Phoenix, where urban expansion meets environmental stressors.

In all these states, ASTM E1105 is more than a standard; it’s a comprehensive plan for resilience and sustainability. Developers relying on this testing method are better equipped to design buildings that last, regardless of their environmental challenges.

Water Intrusion Testing by Specialists and the Expertise Needed for Accurate Results

Water intrusion testing is a specialized field that demands precision. To achieve accurate results, experience and specialized knowledge are essential. Professionals in this field, known as water intrusion specialists, play a key role.

For one thing, these specialists bring a wealth of expertise to the table. They understand the nuances of building materials and how they respond to water pressure. Their ability to interpret test results is crucial for identifying potential issues.

Specialists use sophisticated techniques and equipment to ensure thorough testing. Their insights not only help in preventing water intrusion but also in enhancing construction quality. Selecting a qualified water intrusion specialist can mean the difference between a successful project and costly repairs.

The use of infrared thermography in ASTM E1105 water testing

Thermography is an invaluable tool in the use of water intrusion testing. Thermography is mostly used to locate water inside walls when the removal of wall-covering materials is not possible. Using infrared thermography allows the testing agency access to water leaks that may not have otherwise been accessible or visible with water intrusion testing. Understand that the use of infrared thermography in the ASTM E1105 test is not mentioned in the test standards. But is still acceptable to use.

Selecting the Right Testing Partner

Choosing the right partner for water intrusion testing requires careful consideration. A reliable testing firm will have a proven track record. Look for certifications and experience in various building environments. Furthermore, the ideal partner should also offer a comprehensive suite of services. This includes initial consultations, detailed testing procedures, and follow-up analyses. It’s important that they can adapt their approach to fit the specific needs of your project.

In addition to technical skills, consider their communication capabilities. An effective testing partner will communicate findings clearly and provide actionable recommendations. This collaboration can lead to improved project outcomes and greater peace of mind.

Lastly, consider their familiarity with local conditions. Specialists with regional experience in areas like Los Angeles, Arizona, or Nevada can provide invaluable insights. They understand the unique challenges posed by varying climate conditions and can tailor their testing accordingly.

How much does the ASTM E1105 water intrusion testing cost?

The cost of an ASTM E1105 test administered in Arizona, Nevada, or Los Angeles is usually around $1200. Unlike forensic water intrusion testing which can cost many hundreds and even thousands of dollars, the E1105 water intrusion test is administered for a short period. Testing is usually performed for new construction projects and even residential homes. Regardless of whether the test is administered in conjunction with the ASTM 2128 wall test, it still ranges around $1200.

Conclusion and the Future of ASTM E1105 in Construction

The role of ASTM E1105 in construction is likely to grow. As buildings become more complex, the need for robust standards increases. This test is central to ensuring building envelopes can withstand the challenges of modern climates.

In the future, innovations in construction materials and methods may spur adaptations of ASTM E1105. We can expect a greater emphasis on energy efficiency and sustainable practices. This evolution will align with global trends towards greener, more resilient structures.

Adherence to such standards not only assures quality but also supports environmental goals. As the industry progresses, ASTM E1105 will continue to be a benchmark for excellence. Its relevance is set to increase as builders seek to enhance durability and occupant comfort in the face of evolving climate challenges.